Enhance Recycling Efficiency:

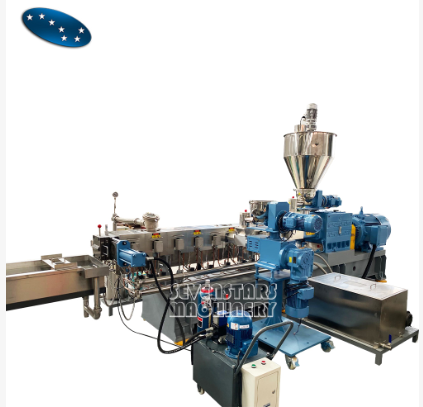

Agglomerators are important for streamlining the recycling process. These devices serve to compress and consolidate sheets of plastic and fiber material to facilitate handling and transportation. With the help of agglomerators, recycling plants such as SEVENSTARS MACHINERY are able to handle bigger volumes of materials in a shorter span of time, which accelerates the recycling process and minimizes the trash dumped into the landfills.

Improving the quality of recycled materials:

Quality is king in film and fiber material recycling. Agglomerators work to enhance the quality level of recycled materials, producing uniform, consistent pellets that can then be reintroduced into manufacturing new products. With an agglomerator, recycling facilities can be confident the recycled materials they create are up to spec to be made into new items, closing the circle and saving on the use of new raw materials.

Reducing waste and increasing sustainability:

One of the greatest advantages to the use of agglomerators in film and fiber recycling is the ability to minimize waste and enhance sustainability. Compacting and binding materials that are considered waste, agglomerators assist us in getting the most out of our limited resources and in avoiding ineffectual and no those ineffective items from being left to waste. This not only decreases the amount of waste that ends up in landfills, but it also saves energy and natural resources, which in turn becomes a more sustainable approach to recycling.

How to make recycling more profi table?

Aside from their ecological contributions, agglomerators are also crucial for enhanced recyclate profitability. Agglomerators not only help recycling facilities like SEVENSTARS MACHINERY lower their production costs and produce more output overall by increasing production efficiency and quality while minimizing waste. It can also help make film and fiber recycling a more economically viable and compelling renewables option for businesses, to the point plastic bottle recycling machine where it convinces even more companies to take the leap and commit to sustainability in the name of the circular economy.

Meeting environmental regulations and standards:

Finally agglomerators are needed to help recycling operations comply with environmental regulations and standards. Agglomerators work to produce the highest quality recycled materials that meet with industry standards and legal allowances so that recycling processes can remain legally compliant and allow for uninterrupted operation. This promotes to improve on environment and public health while contributing to the assurance of consumers and stakeholders, in who those products are in good hands in responsibly sourced materials.

Summary Agglomerators are a necessary piece of equipment in the film pet bottle recycling machine and fiber recycling industry. “By processing the raw feed material efficiently and achieving more consistent agglomeration quality, producer-companies who rely on agglomerators for full-scale production will improve throughput and achieve increased levels of profitability to address customer needs and industrial recycling standards.” This works toward a more sustainable and green environmental goal by reducing waste and the amount of new raw materials that can be used. Therefore, we should all do our part to help recycle and save our earth for our children.